|

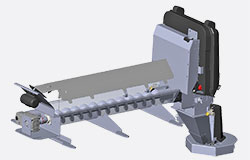

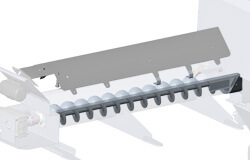

IceStriker™ Tailgate Spreader IceStriker™ SS Spreader IceStriker™ SS Spreader IceStriker™ Pickup Spreader IceStriker™ Truck Spreader IceStriker™ Truck Spreader IceStriker™ SS Tractor Spreader IceStriker™ Tractor Spreader IceStriker™ Drop Spreader |

SprayStriker™ Truck Sprayer SprayStriker™ Sprayer SprayStriker™ Sprayer BrineMixx™ Brine maker SnowStriker™ Pickup V-plow SnowStriker™ Pickup snow plow SnowStriker™ UTV V-plow SnowStriker™ UTV snow plow SnowStriker™ Tractor V-plow SnowStriker™ Tractor snow plow |

DISINFECTION & DUST CONTROL SYSTEMS SprayStriker™ Sprayer SprayStriker™ M-Series SprayStriker™ Cannon Fertilizer SS Spreader HTrack™ |